Drying and Dehydration

Matter under ambient conditions interacts with moisture and volatiles continuously. Exposure to heat and a high airflow over material will induce some form of drying. A material’s ability to resist rapid transitions between wet/hydrated states can be a good measure of stability.

Removal of volatiles from the surface of a solid can have a significant effect on the surface area by collapsing fragile crystals, altering surface energy, and changing the hydrated state of a solid. The degree of wetting and interaction with moisture can significantly change a material’s function and performance, therefore, monitoring its wettability/dry-ability is ever more necessary.

Pharmaceuticals

The ultimate hydration state of a pharmaceutical material may influence several physicochemical properties including physical and chemical stability. For example, the hydration state of crystalline substances is of particular concern in the pharmaceutical industry. For instance, some hydrated materials become amorphous upon dehydration. Also, different hydrate forms can affect the material solubility, dissolution rate, flowability, and compressibility. These factors affect the entire chain of the drug development process from preformulation to solid form development to packaging and storage. Dynamic Vapor Sorption (DVS) allows the fast and accurate determination of channel hydrate formation and loss.

Notes:

Application Note 36: Investigation of Hydrate Formation and Loss Using DVS | Request a copy

Application Note 59: Investigation of Channel Hydrate Formation and Loss Using the DVS | Request a copy

Application Note 501:Environmental Microscopy using the GenRH-A Humidity Generator and Mcell Accessory | Request a copy

Foods and Fine Chemicals

The moisture sorption properties of foods are critical for their shelf-life stability. This is especially true for materials like crackers and noodles which are vulnerable to either temperature or humidity shocks, and in many cases, excess water uptake will lead to poor texture, dissolution, caking, or even mold growth. Food products can take up high amounts of water and may cause them to melt and collapse, rendering them unsalable. The Dynamic Vapor Sorption (DVS) technique is highly effective at demonstrating the physico-chemical behavior of certain foods.

Notes:

Application Note 03: Polymorphism in Spray Dried Lactose | Request a copy

Application Note 503: Investigating Dried Milk Powders Using Optical Microscopy at Different Humidity Conditions | Request a copy

Personal Care Products

Water content is one of the most important parameters controlling skin and hair fibers. Under ambient conditions, human hair can take up as much as 35% of its weight in water before being completely wet. Bleaching, exposure to temperature, and exposure to light, damages the inner structure of the hair. This causes detectable changes in the moisture uptake properties. Therefore, the determination of equilibrium water contents, water sorption isotherms, and hysteresis are fundamental for the hair condition and the same goes for skin cream formulations. The Dynamic Vapor Sorption (DVS) technique provides accurate and reliable testing of these parameters.

Notes:

Application Note 29: Moisture Desorption of Creams and Calculations | Request a copy

Application Note 52: Vapor Permeability of Porous Materials using Payne Diffusion Cell | Request a copy

Fuel Cells

Proton Exchange Membrane Fuel Cells (PEMFC) are an expanding area of research for use as low-pollution power generators for mobile and stationary applications. The PEMFC is composed of a membrane electrode assembly consisting of several layers. There are typically two carbon cloth gas-diffusion layers that allow the concurrent transport of gases and water. These layers are sandwiched between a proton exchange membrane that permits proton transfer from anode to cathode. A critical parameter affecting the performance of these proton exchange membranes is the water content. Water is supplied to the fuel cell by humidifying the gas feed stream. Dynamic Vapor Sorption (DVS) allows the fast and accurate determination of water sorption isotherms and diffusion kinetics over a wide temperature and humidity range.

Notes:

Application Note 39: Measuring Moisture Sorption and Diffusion Kinetics on Proton Exchange Membranes Using the DVS | Request a copy

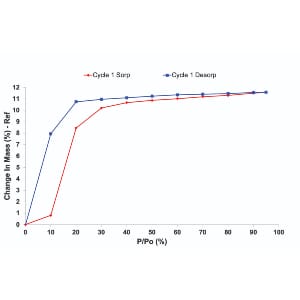

Catalysts and MOF’s

Microporous materials like Metal Organic Frameworks (MOFs) and zeolites have been a novel class of candidates for absorbents, catalysts, and separation processes. For example, a highly flexible micro-porous MOF material exhibits a remarkable capability to capture and separate carbon dioxide from other small gases, including N2, H2, CH4, CO, and O2. The Dynamic Vapor Sorption (DVS) method has been a very useful tool for the characterization of these properties using water and organic vapors at process-relevant temperatures.

Notes:

Application Note 51: Gas Capture and Vapor Separation by Microporous Materials | Request a copy

Application Note 504: Water Vapor Induced Mesoporous Structure Collapse Observed by GenRH with Mcell and FT-IR | Request a copy

Adsorbents

Activated carbons are used widely throughout the industry in a variety of applications from environmental air filtration to solvents and heavy metal recovery. The sorption of moisture by activated carbons is pertinent to many of these applications.

Notes:

Application Note 14: Moisture Sorption of Activated Carbon | Request a copy

Tobacco

The moisture sorption properties of tobacco are critical for the characterization of their drying and shelf-life stability. Tobacco is vulnerable to temperature and humidity shocks which can occur during transport. Once the tobacco becomes wet, it can lose taste, added flavor, or even combustibility. Problems can also occur in very dry tobacco, which can become too fragile to be used in manufacturing. The moisture sorption properties in tobacco can be studied using Dynamic Vapor Sorption (DVS).

Notes:

Application Note 21: Moisture Sorption on Tobacco of Various Origins | Request a copy

Bio and Natural Materials

Biomaterials are materials such as wheat straws that have an abundant and inexpensive natural biopolymer. Biofuel has been attracting attention due to the potential shortages of fossil fuels. One of the crucial steps of producing bioethanol from wheat straw is its pre-treatment before drying which should facilitate the economic feasibility and yield efficient conversion into biofuel. Additionally, paper and most related cellulosic materials exhibit substantial moisture uptake. Dynamic Vapor Sorption (DVS) can effectively assess the sorption and desorption behaviors in biomaterials such as wheat straw and cellulose.

Notes:

Application Note 02: Moisture Sorption of EC Standard Reference Material RM 302 on a DVS-1 Instrument | Request a copy

Application Note 57: Characterization of Wheat Straw for Bio-fuel Application | Request a copy

Application Note 505: Identifying Structural Changes in the Protein Collagen Using Humidity Generation and FT-IR | Request a copy

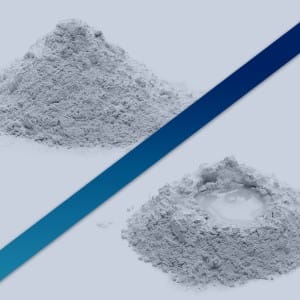

Cements and Building Materials

A critical factor in the long-term storage stability of cement is the rate of moisture uptake under specific storage conditions. Traditionally this is measured by storing large containers of cement under controlled conditions and periodically weighing them over many months or even years. The moisture sorption kinetics can be measured in cement as well as a range of building materials using Dynamic Vapor Sorption (DVS) methodology in a time effective and reliable way.

Notes:

Application Note 09: Measuring the Moisture Sorption of Kinetics of Cements using DVS | Request a copy

Application Note 104: Vapor Sorption Properties of Building Materials using Gravimetric Sorption Instrumentation – an Overview | Request a copy