Our Techniques

Surface Measurement Systems engineer a range of advanced sorption analyzers that employ two main techniques: Dynamic Vapor Sorption (DVS) and Surface Energy Characterization using Inverse Gas Chromatography (iGC). The DVS technique was invented by our founder and managing director, Prof. Daryl Williams in 1991, and the world’s first commercial iGC instrument was entirely designed and engineered by the team here at SMS. Providing a new level of insight, accuracy, and detail in physico-chemical characterization of solids, it’s no surprise they have become the industry standard for laboratories around the world.

Dynamic Vapor Sorption (DVS)

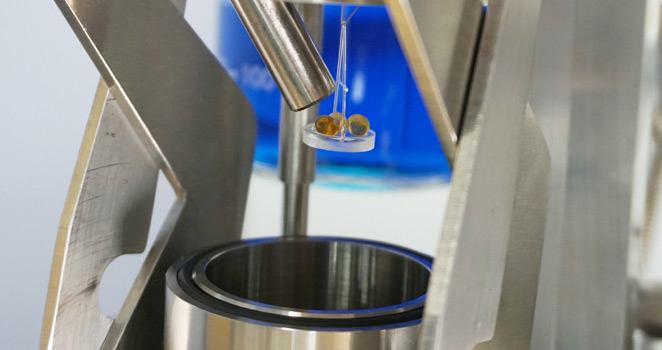

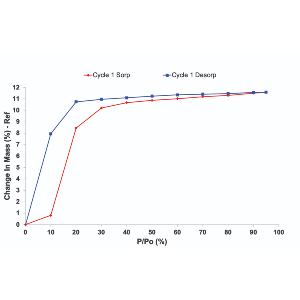

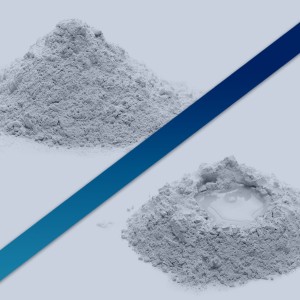

Dynamic Vapor Sorption (DVS), invented by Prof. Daryl Williams over 30 years ago, is a groundbreaking gravimetric technique that measures how quickly and how much of a solvent is absorbed by a sample: such as a dry powder absorbing water. This is achieved by varying the vapor concentration surrounding the sample in a controlled environment and measuring the sample’s change in mass. While water vapor is most commonly used to do this, you can also use a range of organic solvents.

Improving detail and accuracy 20 times compared to contemporary techniques, Dynamic Vapor Sorption is now a valued tool of R&D in laboratories all over the world. It is a vital part of quality control analysis techniques for formulation, scale-up, production, and packaging.

Surface Energy Characterization with Inverse Gas Chromatography (iGC)

Inverse Gas Chromatography (IGC) has become a preferred standard technique in solid-state characterization, especially for amorphous material(s) and several model systems of drug-polymer dispersion. Inverse Gas Chromatography Surface Energy Analyzer (IGC-SEA) by Surface Measurement Systems is the first purpose-built IGC system, with thoroughly engineered solutions, to provide the most accurate and reliable source of surface characterization data.