BTA Frontier

BreakThrough Analyzer

BreakThrough Analyzer

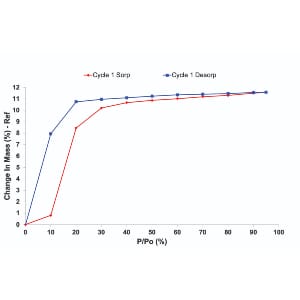

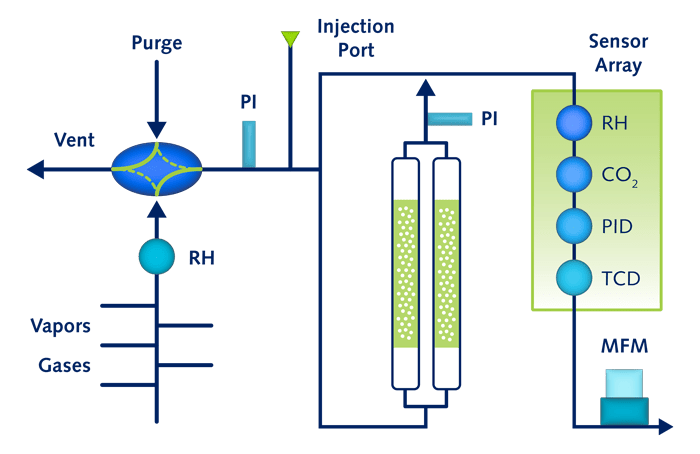

BTA Frontier redefines adsorption breakthrough analysis, delivering unmatched precision in packed bed testing under real-world conditions. With advanced sensors for CO₂, H₂O, and organic vapors, it accurately measures competitive adsorption across various gases and vapors, enabling detailed insights into sample properties and performance.

Designed for efficiency, the BTA Frontier features a dual-sample column for increased throughput, supporting multi-component uptake studies with precise gas-phase mixing and adsorbate detection. Its temperature and flow control ensures exceptional accuracy and confidence in your results.

A Closer Look at the BTA Frontier with Dr. Paul IACOMI

Lead Product Developer, Dr. Paul Iacomi, takes you through the key benefits of the BTA Frontier and the groundbreaking functions it brings to your lab.

Find out more about the BTA Frontier

The BTA Frontier is an exciting new tool in the field of breakthrough analysis, opening new doors for researchers around the world.

To find out more about this groundbreaking new instrument and discover the unique benefits it can bring to your research, request more information from our team, or download the instrument flyer today.