Surface Energy Characterization by

Inverse Gas Chromatography

Until the Inverse Gas Chromatography Surface Energy Analyzer (iGC-SEA) came along, contact angle measurement was the preferred method for measuring surface energy. Following the creation of the iGC-SEA instrument by Surface Measurement Systems, Inverse Gas Chromatography (iGC) became an essential tool for characterizing particles and other non-planar materials. With this groundbreaking instrument employing the iGC technique like never before, surface energy characterization is now the method preferred in laboratories worldwide.

But how does it all work?

What is Inverse Gas Chromatography?

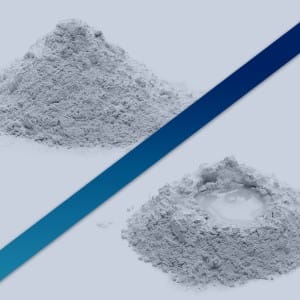

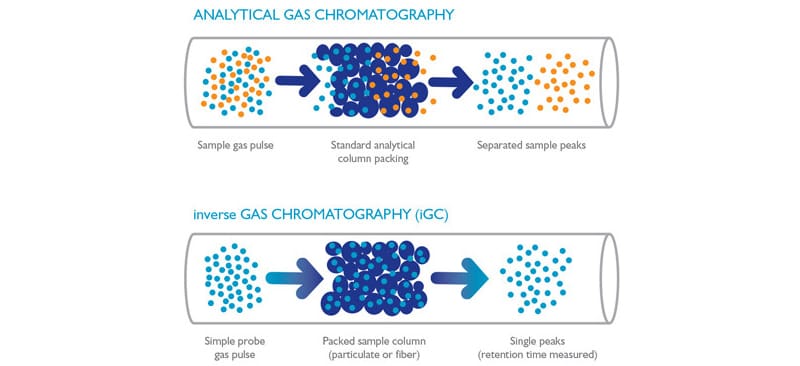

Inverse Gas Chromatography (iGC) is a gas-solid technique for characterizing surface and bulk properties of powders, particulates, fibers, films, and semi-solids. A series of vapor pulses are injected through a column packed with the sample of interest. Unlike traditional analytical gas chromatography, iGC is a physical chemistry technique using vapor probes with known properties to characterize the unknown surface/ bulk properties of the solid sample.

Due to its accuracy and reliability, Inverse Gas Chromatography is now a widely used solid-state characterization technique in many industries to understand solid product behavior.

What is Surface Energy (SE)?

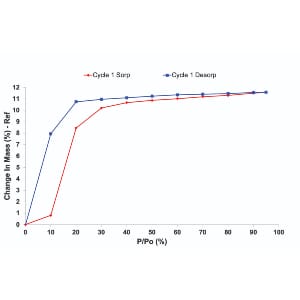

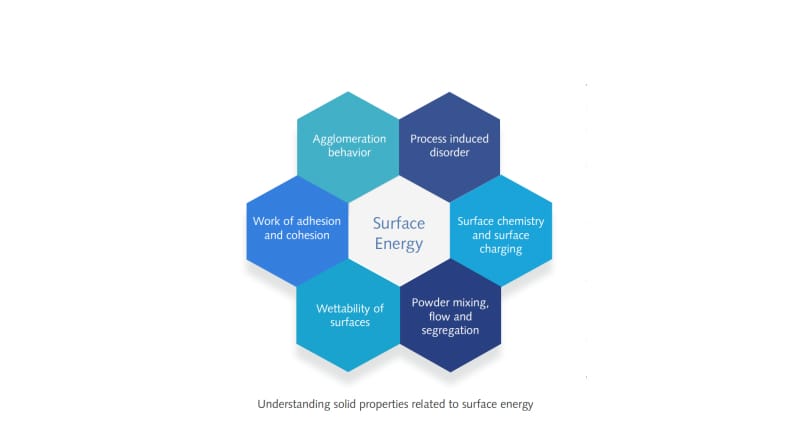

Surface energy γ, is the principal characteristic measured by the IGC. The surface energy of a solid is analogous to the surface tension of liquid and it is a measure of attractive intermolecular forces on a solid surface. It is the same intermolecular forces that are responsible for the attraction between powder particles, with other solid, liquid, and vapor molecules which can occur via long-range van der Waals forces (dispersion forces) and short-range chemical forces (polar forces). Surface energy values (dispersive and polar) correlate to several key solid properties including wetting, dispersibility, powder flowability, agglomeration, process-induced disorder, adhesion/cohesion, static charge, adsorption capacity, and surface chemistry.

iGC-SEA

Inverse Gas Chromatography Surface Energy Analyzer (IGC-SEA) is a designed and purpose-built IGC system. The heart of its innovation is the patented injection manifold system which generates accurate solvent pulse sizes across a large concentration range, resulting in isotherms at unprecedentedly high and low sample surface coverages. This allows for the accurate determination of surface energy heterogeneity distributions. The fully automated iGC-SEA can be operated at different solvent vapor, flow rates, temperature, humidity, and column conditions.

iGC-SEA has a unique data analysis software, specifically designed to determine surface energy heterogeneity, isotherm properties, and related physical characterization parameters. Further, bulk solid property experiments resulting from probe-bulk interaction and using solubility theory are now possible. It automatically and directly provides a wide range of surface and bulk properties of the solid samples and gives more accurate and reliable data than manual calculations. It also has a humidity control option. The impact of humidity and temperature can be determined for the physicochemical properties of solids such as surface Tg, BET-specific surface area, surface energy, wettability, adhesion and, cohesion.

Founding Principle of iGC-SEA

iGC is a gas-solid phase technique for characterizing surface and bulk properties of powders, particulates, fibers, films, and semi-solids. An experiment consists of a series of vapor pulses injections eluting through a column packed with the sample under examination.

The vapor’s retention time is measured by a Flame Ionization Detector (FID). Varying the vapor probe molecule, flow rate, temperature, or column conditions helps to determine a wide range of surface and bulk properties of the sample.

Contact angle measurement is a commonly used method for measuring Surface Energy, but it is has limitation on particle and other non-planar materials. For this reason, now inverse gas chromatography is the proven and preferred method for surface energy analysis of such materials.

iGC-SEA compared to Contact Angle (CA) and Atomic Force Microscopy (AFM)

| Surface Energy Analyzer (SEA) | Contact Angle (CA) | Atomic Force Microscopy | |

|---|---|---|---|

| Sample Form | Powder, fibers, films, nanoparticles, granules, and semi-solids | Flat samples- easy Particulate – difficult | Flat smooth samples-easy Particulate- difficult |

| Nature of Measurement | Vapour adsorption isotherm method | Liquid-solid contact-Dissolution-Swelling | Contact/adhesive force between probe and sample |

| Reproducibility and Repeatability | Very good reproducibility and repeatability (RSD%=1) | Reproducibility varies-need to consider contact angle hysteresis Cannot do repeats | Significant data scatter in both-surface topography can affect data. Difficult to get statistically significant data sets |

| Experimental Conditions | Controllable T and %RH | Typically ambient T and %RH condition | Strict controlled T- poor humidity control |

| Theoretical Validity | Well-developed theoretical models for determining surface energy | OK for flat surfaces, very problematic for particulates | Need JKR or DMT theory to analyze data based on the known radii of the AFM probe |

| Time for Measurement | Single set of measurements 1 hour | Set of measurements less than 1 hour | Set of measurements less than 1 hour, but many hours to set up |

| Mapping of Properties | Surface energy heterogeneity well established | Possible in theory, but not practical | Possible in theory, but not practical because of data variability |

iGC-SEA compared to Traditional iGC

| Home Built iGC | iGC-SEA | |

|---|---|---|

| Injected phase | Liquid with a special tool (headspace), it can be vapor | Vapor |

| Column design | Circular or U shape glass tube | Straight silanized glass tube |

| No. of samples tested at the same time | Single | Twin sample holders |

| Detector | FID or TCD | FID only due to the humidity option |

| Analysis Software | Peak analysis and manual data analysis | Peak analysis provides physicochemical data for the solid sample |

| Carrier gas flow rate | Soap bubble flow meter | Mass Flow Controller |

| Dead Volume Measurement | Manual | Automatic |

| Pressure Drop Measurement | Manual with special device | Automatic |

| Data Analysis | Manual | Automatic |

| Sample packing | Non-standard apparatus | Column packer accessories |

| Humidity Control | Rare | Standard Option |

| Sample Size | 10mg to ≈1g | 1mg to 10g |

Surface Energy Characterization with Inverse Gas Chromatography (iGC)

Contact angle measurement is a commonly used method for measuring Surface Energy, but it wasn’t until the creation of the iGC-SEA instrument by Surface Measurement Systems that it became an essential tool for characterizing particles and other non-planar materials. With this groundbreaking instrument employing the IGC technique like never before, Surface Energy Characterization is now the preferred method in laboratories worldwide.