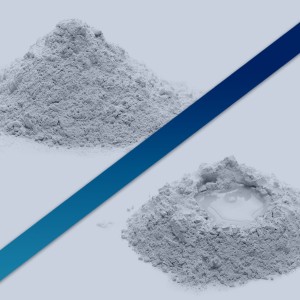

This educational webinar explores the use of surface energy measurements as related to granulation performance.

In particular, this session focuses on the well-established vapor sorption technique of Inverse Gas Chromatography (IGC). This session discusses several case studies on how surface energy measurements can be used to help formulate and characterize both wet and dry systems. In addition to granulation case studies, other unit common powder operations, such as milling, will be presented and related to surface properties.

The research on fuel cells as alternative power generators is growing significantly. The humidity of the feed stream is vital to the performance of proton exchange membrane fuel cells. Also, the surface energies of fuel cell components are related to electro-osmotic drag, back diffusion of water, and water retention.

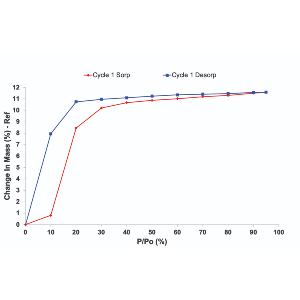

The surface energies of different fuel cell components have been measured via Inverse Gas Chromatography (IGC SEA) over a range of relative humidities. Therefore, characterizing thermodynamic properties of wetting, such as internal surface energy, over a range of RHs is vital to the successful development of PEMFC components. Additionally, Water content and flux are important properties for proton exchange membrane fuel cell performance. The water sorption isotherms have been determined using Dynamic Vapour Sorption (DVS).

This workshop includes two in-depth presentations discussing the latest research in DVS technology and its applications in fuel cell research.

This in-depth online workshop explores innovative sorption techniques, technology, and applications for the study of porous materials.

Employing recent research and case studies, attendees gained a keen understanding of the groundbreaking DVS technique, and the unparalleled detail and accuracy it grants in the study of porous materials, VOCs and MOFs.

Agenda:

-Ionic liquids and ionogels for water sorption in low-grade heat-driven applications with Dr. Giulio Santori, Senior Lecturer, University of Edinburgh

-Impact of relative humidity on hydrophobicity and selectivity of porous adsorbents for VOC capture with Elwin Hunters Sellars, PhD Student, Imperial College London

-Novel Porous Materials for Carbon Capture Utilisation and Storage: Studies Under Relevant Industrial Conditions with Paola Saenz Cavazos, PhD Student, Imperial College London

Surface Measurement Systems and the University of British Columbia collaborated to provide three in-depth presentations exploring the latest research, case studies, and findings. This workshop offers unparalleled insight into the use of sorption science techniques in the field of cellulosic materials and characterization.

Almost all production stages involve moisture sorption and drying processes, which would affect the physical and chemical stability of the materials.

For food materials, the moisture sorption properties are critical for shelf-life stability. This is especially true for materials like biscuits or crackers which are vulnerable to either temperature or humidity shocks. This study uses the Dynamic Vapour Sorption (DVS) technique to focus on the influence of sample size and morphology on the moisture sorption behavior of food materials including biscuits and crackers.

This free online workshop explores how you can use Vapor Sorption Techniques to characterize construction materials. The in-depth workshop covers Dynamic Vapor Sorption (DVS) and Inverse Gas Chromatography (iGC) technology and their applications.

Organized in partnership with the University of Luxembourg, this session is a vital resource for anyone working in the following fields of research:

-Cement & concrete

-Asphalt & bitumen

-Natural & Synthetic fibres

-Carbon fibre & graphene

-Natural stones

-Wood

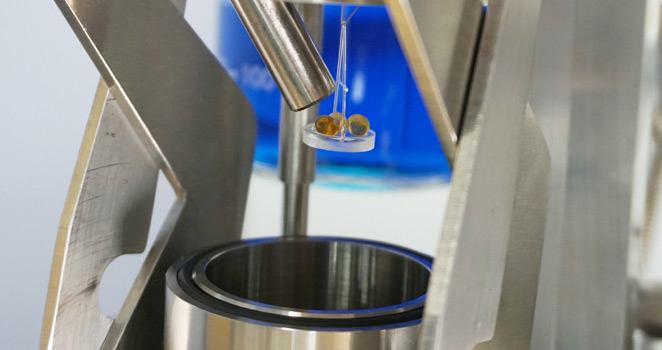

Traditional BET surface area measurements are typically performed by volumetric, gas sorption techniques. These methods require exposing the material of interest to very low pressures (10-3 Torr and below) and cryogenic temperatures (77K). These conditions can have deleterious affects on many classes of materials; including pharmaceuticals, foods, cellulose-based samples, and natural ingredients. In particular, low pressures and temperatures can cause structure collapse or phase changes on fragile solids.

Flow-based sorption techniques, like Dynamic Vapor Sorption (DVS) and Inverse Gas Chromatography (IGC) can be performed at atmospheric pressure and room temperature. These techniques can be used to determine BET surface areas at industrially relevant and environmental storage conditions. In addition, these techniques can be performed over a wide range of relative humidity conditions, which allow surface characterization and determination of surface areas at ‘real-world’ conditions.

This educational seminar overviews the BET surface area principle by DVS and IGC. Also, it compares results with volumetric measurements and highlight the application of DVS and IGC surface area measurements on a range of materials.

Accurate and detailed insight into sorption properties and surface energy is essential to sector of consumer product research; but nowhere is this more important than in the food sector.

This free-to-attend online workshop explores two innovative techniques, Dynamic Vapor Sorption (DVS) and Inverse Gas Chromatography (IGC), and how they can provide unparalleled insight in the study of food.

Vapor pressure is defined as the pressure exerted by vapor in thermodynamic equilibrium with its condensed phases (solid or liquid) at a given temperature in a closed system. It is an important physicochemical property for many applications including human health, environmental protection, vapor phase deposition processes, lubricants operational life and separation processes. In addition, the vapor pressure thermodynamic data can be used to calculate enthalpies of vaporization or sublimation. Therefore, the accurate determination of vapor pressure is fundamental for the development of models simulating the behaviour of chemicals in industrial processes or outdoor environments. There are several methods for measuring vapor pressures, as it is difficult for a single experimental method to cover entire range of vapor pressures from less than 10-15 to 105 Pa.

In this webinar, we discussed the Knudsen effusion method and static method for vapor pressure measurement. The Knudsen effusion method is used for measuring sublimation or evaporation processes below 100 Pa in the temperature range from 293 to 673K. The static method has been developed to extend the measured pressure range up to 105 Pa in the temperature range between 293 and 323K. Also, it is capable of measuring vapor pressures of liquid samples, or crystalline solids.

This webinar covers an in-depth introduction to the Inverse Gas Chromatography – Surface Energy Analyser (iGC-SEA) technique and the concept of surface energy.

It explores the versatility of the iGC-SEA technique and how it can be used in the study of pharmaceuticals, polymers, carbon materials and fibres. The case studies presented highlight the use of the system to measure BET specific surface area, surface energy and surface heterogeneity. Studies also demonstrate the effects of changing conditions of temperature and humidity on materials.