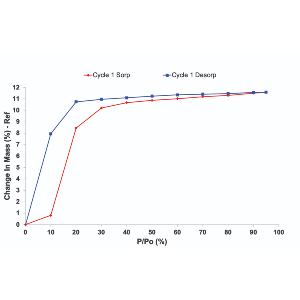

Moisture has a large impact on the mechanical, physical and chemical properties of many materials. Organic solvent sorption studies can be particularly useful for understanding the surface and bulk properties of different materials, such as BET surface area, porosity, diffusion and permeability.

This webinar will highlight a series of experimental methods of water and organic solvent sorption characterization techniques for determining vapour sorption isotherms of titanium oxide using Dynamic Vapor Sorption (DVS).

Presented by Prof. Daryl Williams from Imperial College London, this educational and informative webinar discussed the study of the role of solid state surface chemistry on the high shear granulation performance of model pharmaceutical solids.

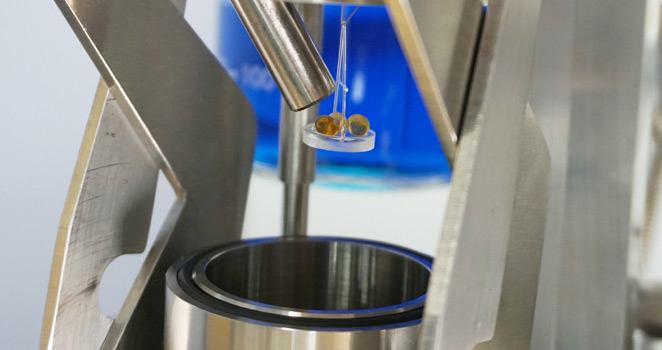

The interaction of a solid with its surroundings is through the available surface area for adsorption of gas or vapor molecules. This also allows probing of material surface including irregularities and pores. One of the most successful methods is based on the adsorption method of Brunauer, Emmett and Teller (BET), which is based on the physical adsorption of a vapour or gas onto the surface of a solid. Traditionally, sorption studies were carried out at low temperatures to obtain nitrogen isotherms at 77 K, which were then used to calculate BET surface areas.

In this informative and educational webinar, Dr. Anett Kondor will compare dispersive and acid-base contributions to adhesion in man-made cellulose fibre-reinforced thermoset composites, various nanofiller- polyurethane (thermoplastic) composites, and surface modified silk particles. These interactions are measured by iGC.

Dr. Anett Kondor is the iGC-SEA Product Manager and Product Specialist of Surface Measurement Systems and has 13 years of experience in gas chromatographic (GC and iGC) techniques. She has published several research works in peer-reviewed journals collaborating with research groups around the world (Deakin University – Australia, Composite Innovation Centre Canada, Teagasc Ireland, Boku University Austria, Liverpool John Moores University UK and Givaudan Switzerland).

In this webinar, Dr. Damiano Cattaneo focused on:

- An introduction to the dynamic vapour sorption, with reference to the historical development of the methodology, DVS principle, and the standard method of data collection

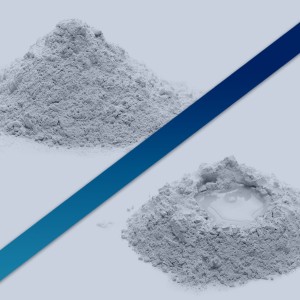

- A description of different methodologies that can be used to calculate amorphous content

- A focused analysis on the theoretical and practical measurement of BET surface area

- The technology that allows the DVS to perform this type of measurement (Speed of Sound sensor).

In this webinar, Professor Daryl Williams discussed that in many of the particle processing operations, the surface energy and the surface area of the starting, intermediate or final products is a key factor in understanding the processing operation and or the final product performance. Inverse Gas Chromatography played a major role on this.

n this webinar, Dr. Jürgen Thun highlighted the importance of Dynamic Vapor Sorption in developing a sound solid form control strategy.

Speaker: Dr. Jürgen Thun Principal Scientist, Group Leader Particle Design F. Hoffmann-La Roche Ltd., Pharma Technical Development Synthetic Molecules Solid State Science

Inverse Gas Chromatography (iGC) can be used to determine the surface properties of many materials. In some cases, as well as surface adsorption, there is also bulk sorption of the iGC probe molecules, allowing bulk materials properties to also be determined. Presented by Prof. Daryl Williams, the webinar presented the use of iGC technique for determining the Tg of polymeric materials and Tg of polymer coatings when applied to highly crystalline fibres, such as fibre sizing and coatings.

In this webinar, Prof. Williams explained the importance of process humidity as a key parameter when designing or selecting adsorbents in realistic process conditions. Additionally, the methods used in this study provide a simple and reproducible way of testing porous materials for applications requiring or involving high levels of relative humidity.

In this webinar, Dr. Damiano Cattaneo highlighted some examples of case studies such as amorphous content calculation and glass transition Tg RH (the critical relative humidity at the specific glass transition temperature). Moreover, we will focus on the characterization of an in situ study of the camera and Raman applications during a DVS experiment.