Sorption Overview Series #1

The Basics: Gas and Vapor Sorption Techniques

Sorption properties are essential for determining key performance factors across a range of industries and play a vital role in the research and development of advanced industrial solutions.

In this new blog series, we explore and compare the various techniques material scientists use to measure the sorption of vapors and gases in different solids. Join us as we dive into these methods and evaluate the strengths and limitations of each.

In the first article of the series, we introduce the fundamentals of sorption techniques to provide a solid foundation for our overview of advanced gas and vapor sorption methods.

Sorption Techniques

|

We begin this series by clarifying key terms related to sorption variables and how probe molecules are introduced into a system. This foundation sets the stage for a broader look at common measurement techniques, including their benefits and limitations. Throughout this series, we will use the terms “gas” and “vapor” interchangeably to refer to molecules in the gaseous phase used to probe the material—also known as the sorbate. Strictly speaking, a gas is a fluid that cannot be liquefied by increasing its pressure (i.e., a fluid above its critical temperature). Several commonly used experimental techniques measure gas and vapor sorption, including:

These techniques have wide practical applicability: first, in determining fundamental material properties such as surface area, porosity, surface energy, hygroscopicity, and contact angle; and second, in assessing a material’s performance for applications that rely on sorption behavior—such as heterogeneous catalysis, API stability, water harvesting, and gas separation. The data obtained from different techniques can vary, and a variety of factors should be considered when choosing the most suitable method. Each technique has its own set of advantages and limitations that influence this decision. Factors that guide this choice include: |

|

|

Stay tuned for the next article in the Sorption Series

Check back soon to catch the next article in the series: Understanding Sorption Terminology: Temperature and Pressure.

In the meantime, benefit from a range of free educational sorption materials on our online eLearning Portal: The Sorption Academy.

Use the link below to access this for free today.

Unlocking Surface Energy Insights with the iGC-SEA Nova

iGC-SEA Nova Case Study

The 2024 Carbon Capture Innovation Prize Launches:

A New Research Competition

Singapore, April 2024 | Surface Measurement Systems is thrilled to announce the launch of the 2024 Carbon Capture Innovation Prize, a prestigious competition designed to accelerate research in the field of carbon capture technology. In a groundbreaking initiative alongside MOF2024, this challenge aims to support researchers seeking to revolutionize the way we employ materials to combat carbon emissions via carbon capture, and to highlight their pioneering research work. The final winner of this Prize will be awarded a DVS Carbon instrument valued at $150,000, a state-of-the-art scientific instrument that accurately measures CO2 uptake in materials under a range of real-world conditions.

| Fostering Innovation and Sustainability

As the world grapples with the escalating challenges of climate change, the need for innovative and sustainable solutions has never been more critical. The 2024 Carbon Capture Innovation Prize aims to harness the power of scientific ingenuity to develop new materials and technologies capable of capturing CO2 efficiently from atmospheric and industrial sources, thus contributing to a more carbon-neutral society. Surface Measurement Systems is committed to supporting global researchers who working on this important topic. About the Challenge Run in coordination with the world leading MOF2024, taking place 15 – 19 July 2024 in Singapore, this challenge invites professionals, academics, and innovators to submit a brief proposal on how a DVS Carbon would help their research ambitions. This state-of-the-art sorption analyzer is designed for precise measurement of CO2 capture in solid state materials across various test conditions. Competition entrants will submit a short research proposal on how they propose to employ this instrument to investigate new and exciting possibilities in materials for carbon capture. A panel of 5 international expert judges will evaluate the research proposals submitted to determine a final shortlist, and the winner. Eligibility and Awards The contest is open to professional researchers (no student applicants) affiliated with academic institutions, government laboratories, or startup companies. Entrants must have the authority to install the awarded instrument in their designated research area/laboratory. The winning submission will be awarded a DVS Carbon instrument, valued at over $150,000, to significantly bolster their research capabilities in discovering new materials for CO2 capture. The DVS Carbon The latest instrument in Surface Measurement Systems’ Dynamic Vapor Sorption series, the DVS Carbon sets a new industry benchmark for evaluating solid-state materials for CO2 capture. Capable of measuring uptake at a wide range of CO2 concentrations, temperatures, and in the presence of moisture, the DVS Carbon opens up exciting possibilities for predicting performance in new adsorbent materials for use in the CCUS space. This award aims to get the research community thinking about what they could achieve with this instrument, and provide a gateway for them to get supporting in achieving their goals. Submission Guidelines and Evaluation Criteria Proposals must be comprehensive, detailing the team’s background, research objectives, methodology, and the potential impact of their work on climate change solutions. Submissions will be evaluated based on innovation, scientific rigor, impact potential, and clarity. A panel of independent reviewers will select the winner and runners-up, with a preference for early career researchers in the event of a competition tie. An application form is available here Recognition and Collaboration The winner and four runners-up will be showcased at an official ceremony during MOF2024 conference , gaining substantial exposure among leading researchers. Additionally, the winner will have the opportunity to share their findings in future webinars hosted by Surface Measurement Systems, fostering collaboration and knowledge exchange within the scientific community. Join the Movement Towards a Carbon-Neutral Future Surface Measurement Systems invites global researchers to partake in this unique opportunity to contribute to a more sustainable future, and secure a hugely valuable research tool for developing advanced material solutions. The deadline for submissions is June 17th, 2024, with the winner to be announced during the MOF2024 conference. For more information on the Carbon Capture Innovation Challenge and how to submit your proposal, please visit www.sorptionhub.com/mof24-cc-prize |

About Surface Measurement Systems

Surface Measurement Systems is at the forefront of developing innovative technologies for material science. Specializing in advanced analytical instruments, the company is dedicated to supporting research that addresses some of the most pressing environmental challenges of our time.

Join us in shaping the future of carbon capture technology and making a tangible impact on reducing global warming.

Unlocking Surface Energy Insights with the iGC-SEA Nova

iGC-SEA Nova Case Study

Unlocking Breakthroughs:

8 Ways DVS is Essential to

Pharmaceutical Research

Moisture sorption properties stand at the forefront of pharmaceutical material considerations, exerting profound effects on storage, stability, processing, and performance. Guided by the stringent standards of regulators around the world, moisture, far from being a mere impurity, commands strict monitoring and control, especially within drug substances.

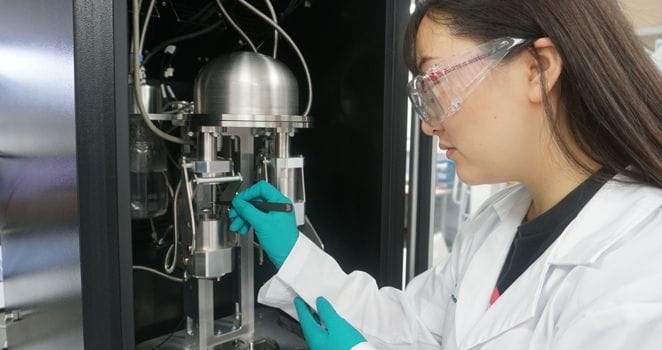

The implications of moisture content extend across critical facets of pharmaceutical products, influencing crystallinity, storage modulus, permeability, density, and the melting point, with a pronounced impact on amorphous materials. Recognizing the need for a nuanced approach to moisture analysis, the Dynamic Vapor Sorption (DVS) technique was developed by Surface Measurement Systems in the early 1990s.

This technique, now a cornerstone in pharmaceutical research, offers a rapid, highly-sensitive, and automated method for studying moisture sorption properties across a spectrum of materials. Below we unravel the multifaceted benefits of employing DVS in the analysis of pharmaceutical materials.

1. Compliance with pharmaceutical regulations

The Dynamic Vapour Sorption (DVS) technique is instrumental in meeting stringent US pharmaceutical standards by providing a rapid, highly sensitive, and continuous approach to studying moisture sorption properties. Developed by Surface Measurement Systems, the DVS instrument ensures compliance with US Pharmacopeia guidelines by actively measuring and controlling relative humidity and a wide range of organic vapour concentrations. This precision in environmental control enhances understanding across various applications, including the determination of moisture content, sorption isotherms, and the characterization of hydrates and solvates. Additionally, DVS proves valuable in assessing hygroscopicity, a crucial factor in preformulation activities and the selection of drug crystal forms.

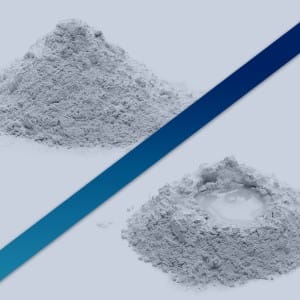

2. Provides unparalleled insight into moisture-induced phase changes

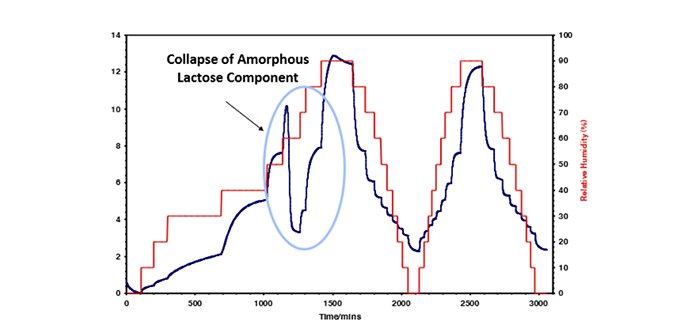

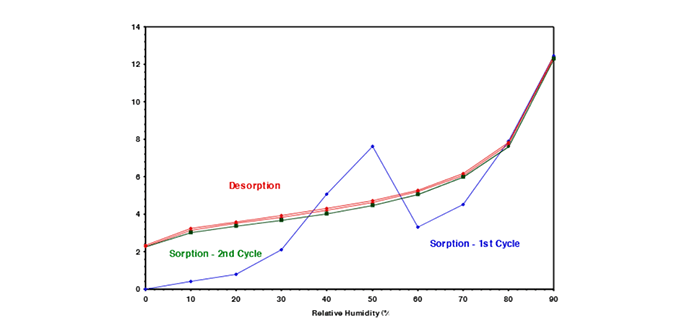

Understanding moisture-induced phase changes is vital in the development of pharmaceutical materials, with a focus on crystallinity, amorphous substances, and hydrate and solvate formation. DVS enables precise examination of amorphous solids, crucial for understanding the critical humidity at which glass transitions occur, impacting storage and processing conditions. Linear relative humidity ramping experiments and 2-dimensional phase diagrams contribute to determining optimal stability conditions for amorphous pharmaceutical ingredients.

Furthermore, DVS plays a vital role in characterizing hydrate and solvate formation, offering valuable data for pharmaceutical development. It detects different hydrate forms and studies stoichiometric solvates, providing a versatile methodology for various solvent concentrations. The integration of DVS with in-situ vibrational spectroscopy enhances the understanding of moisture-induced phase changes by monitoring molecular vibrational characteristics. In summary, DVS is an indispensable tool for unravelling the complexities of moisture-induced phase changes in pharmaceuticals, encompassing crystallinity, amorphous materials, and hydrate and solvate formation.

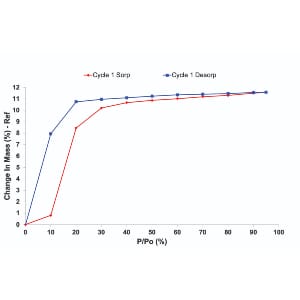

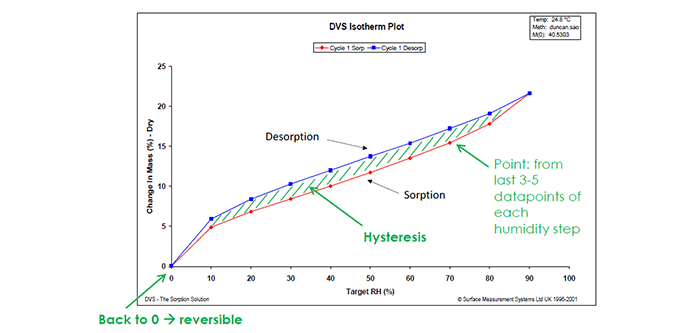

3. Understand the moisture sorption hysteresis of your materials

When attempting to analyse moisture sorption hysteresis, the DVS technique has a unique ability to swiftly measure sorption kinetics and determine moisture diffusion coefficients, facilitating a comprehensive understanding of material transformations. This rapid and continuous measurement capability is in stark contrast to the prolonged timelines associated with traditional desiccator jar methods. DVS’s role extends beyond the laboratory, offering insights into formulation optimization, manufacturing, and quality control processes. By studying moisture sorption hysteresis, researchers can make informed decisions about storage requirements, ensuring the stability and performance of pharmaceutical materials. The instrument’s simultaneous determination of sorption and desorption isotherms on the same sample is particularly valuable, shedding light on dynamic material behaviour under varying humidity conditions. This nuanced understanding aids in tailoring formulations for optimal performance, ultimately contributing to the efficiency and quality of pharmaceutical production.

4. More than just powders – gain vital insight on pharma packaging materials

Dynamic Vapour Sorption (DVS) emerges as an indispensable tool in pharmaceutical research, particularly in the realm of studying packaging materials. DVS facilitates the measurement of diffusion coefficients for films, powders, and fibers, providing valuable insights into the permeability and transport properties of pharmaceutical packaging materials. By conducting real-time mass change experiments, DVS allows for the determination of diffusion coefficients over a range of temperatures, offering a nuanced understanding of how these materials interact with water vapor. This capability is particularly beneficial for packaging applications, where the diffusion into films can be critical for ensuring the stability and integrity of pharmaceutical products during storage and transportation.

Furthermore, DVS proves instrumental in evaluating water vapor transmission rates (WVTR) for pharmaceutical packaging materials. The innovative Payne style diffusion cell, designed for this purpose, enables the measurement of the rate of diffusion of water vapor through thin films. This information is crucial for assessing the effectiveness of packaging barriers in preventing moisture ingress, which is vital for maintaining the quality and shelf-life of pharmaceutical products. The combination of diffusion coefficient determination and WVTR measurement using DVS provides comprehensive data for optimizing pharmaceutical packaging, contributing to the development of packaging solutions that meet stringent quality standards and regulatory requirements.

5. Gain detail insight into sorption mechanisms of pharma materials

Having a detailed understanding of the sorption mechanisms of any given material is essential in determining the effective use of pharmaceutical materials, including excipients, drug formulations, and packaging films. One significant benefit of DVS is its ability to generate moisture sorption isotherms, providing crucial insights into the material’s response to varying relative humidity (RH) levels. Unlike traditional methods such as the desiccator jar, DVS enables continuous measurement of sorption kinetics, allowing for the determination of moisture diffusion coefficients and the measurement of sorption and desorption isotherms on the same sample. This real-time capability significantly accelerates the process, reducing the time required for determining isotherms from weeks or months to hours or days. Additionally, DVS facilitates the measurement of moisture-induced phase changes, aiding in the understanding of critical humidity thresholds for glass transitions and potential issues such as powder caking.

As previously mentioned, the DVS technique proves instrumental in characterizing hydrates and solvates of pharmaceutical materials. It enables the detection and characterization of hydrate formation based on environmental relative humidity, allowing for a deeper understanding of the influence of hydration states on physico-chemical properties. DVS can also extend its applicability to studying stoichiometric solvates, providing valuable information on solvate formation and stability. The technique’s combination with in-situ vibrational spectroscopy enhances its capabilities, allowing for the monitoring of molecular vibrational characteristics during hydration state changes. Overall, DVS emerges as a powerful tool for predicting dispersion in liquid solvents, offering insights into sorption kinetics, isotherm characteristics, and the formation of hydrates and solvates critical for pharmaceutical development and quality control.

6. Understand the importance of sorption and desorption curves with continuous measurement of sorption kinetics

Crucial insights into moisture sorption properties through the analysis of sorption and desorption isotherms are vital to ensuring stability in materials for new coatings and treatments. By continuously measuring sorption kinetics in real-time, DVS enables the determination of moisture diffusion coefficients and the exploration of moisture sorption hysteresis on the same sample. This dynamic approach accelerates data collection, offering a nuanced understanding of how pharmaceutical materials interact with water vapor at various relative humidity levels, essential for assessing storage conditions and preventing potential degradation risks.

Sorption kinetics data obtained from DVS play a pivotal role in developing coatings and treatments aimed at maintaining product stability. Understanding the rate of moisture absorption and release empowers researchers to design precise coatings, preventing moisture-induced phase changes that could compromise the stability of amorphous pharmaceutical ingredients. DVS’s real-time, detailed sorption kinetics data facilitate the customization of coatings and treatments, ensuring materials withstand environmental humidity, contributing to the formulation of pharmaceutical products that meet stringent stability and quality requirements throughout their lifecycle.

7. Impact of moisture in Hydrolysis and Drug Degradation

Crucial insights into moisture sorption properties through the analysis of sorption and desorption isotherms are vital to ensuring stability in materials for new coatings and treatments. By continuously measuring sorption kinetics in real-time, DVS enables the determination of moisture diffusion coefficients and the exploration of moisture sorption hysteresis on the same sample. This dynamic approach accelerates data collection, offering a nuanced understanding of how pharmaceutical materials interact with water vapor at various relative humidity levels, essential for assessing storage conditions and preventing potential degradation risks.

Sorption kinetics data obtained from DVS play a pivotal role in developing coatings and treatments aimed at maintaining product stability. Understanding the rate of moisture absorption and release empowers researchers to design precise coatings, preventing moisture-induced phase changes that could compromise the stability of amorphous pharmaceutical ingredients. DVS’s real-time, detailed sorption kinetics data facilitate the customization of coatings and treatments, ensuring materials withstand environmental humidity, contributing to the formulation of pharmaceutical products that meet stringent stability and quality requirements throughout their lifecycle.

8. Unlock advanced applications with organic solvents sorption analysis

When applied with organic solvents, the Dynamic Vapour Sorption (DVS) technique unlocks advanced applications that significantly contribute to characterizing and determining physicochemical properties, particularly surface area, in pharmaceutical materials. DVS instruments, with their unique capability to actively measure and control the concentration of a broad range of organic vapours, extends its utility beyond water vapour analysis. This innovative feature allows researchers to explore the interaction between pharmaceutical materials and organic solvents in real time. Notably, the DVS technique applied to organic solvents proves instrumental in determining surface area using the BET (Brunauer-Emmett-Teller) method. Unlike traditional volumetric techniques, DVS experiments are performed at atmospheric pressure and room temperature, mitigating the risk of altering the fragile structure of materials.

The application of DVS with organic solvents is exemplified in the determination of the BET surface area for pharmaceutical materials, such as Metformin Hydrochloride, showcasing the technique’s advantages over conventional methods. The dynamic flow nature of DVS enables rapid equilibration, providing efficient and accurate measurements of surface area with relatively small sample sizes. This capability is particularly advantageous for new drug entities or materials with very low surface areas. Therefore, the DVS technique, when coupled with organic solvents, emerges as a powerful tool for pharmaceutical researchers, offering a dynamic and precise approach to surface area determination and advancing the characterization of materials critical for drug development and quality control.

Conclusion:

In conclusion, the Dynamic Vapour Sorption (DVS) technique presented here demonstrates its pivotal role in unraveling the complexities of moisture sorption, hydrate/solvate formation, and physicochemical properties in pharmaceutical materials. Its wide range of applications, from understanding moisture-induced phase changes to characterizing surface area with organic solvents, showcases the versatility and precision of DVS technology.

For those seeking to delve deeper into these advanced applications and explore the full potential of our DVS, find out more about our products on our company page, or read a full Pharma Overview Scientific Note for DVS using the link below.

Unlocking Surface Energy Insights with the iGC-SEA Nova

iGC-SEA Nova Case Study

Season’s Greetings from Surface Measurement Systems

| It’s been an important year for Surface Measurement Systems globally, full of bold new steps for the business. Among the many exciting developments was the launch of our new contract analysis business, Particle Characterization Laboratories, in Hyderabad, India back in February. From there we’ve continued to grow and expand our sales and service teams across the world, elevating our customer engagement even further. This is coupled with an expansion of our research and development as well as the science teams, to support our plans for product development. A key feature of 2023 has been new faces! As we expand the global ambitions for the business, I have had the pleasure of welcoming many new staff to Surface Measurement Systems globally.

The last 12 months saw the release not only of a brand-new website and online customer portal (www.sorptionhub.com), but Surface Measurement Systems also launched ground-breaking new instruments for developing new carbon capture materials; the DVS Carbon family. These products are being closely followed by two innovative Break Through Analysis (BTA) products; the BTA Horizon and BTA-Frontier. And of course, we continue to improve and develop our current products, including a new family of improved microbalances and an updated IGC-SEA product with a high temperature capability. We look forward to continuing to serve the global sorption community with innovative solutions, unparalleled aftersales care, world-leading scientific support in an exciting 2024. Festive greetings from the Surface Measurement Systems team! |

Prof. Daryl Williams, Founder & MD of SMS, Inducted as a Fellow of the Royal Academy of Engineers

DISCLAIMER: Story not to be shared on social media

Among the many exciting developments at Surface Measurement Systems in 2023, our Founder & MD, Prof. Daryl Williams, was recognized for his lifelong contributions to the field of engineering by being elected a Fellow of the Royal Academy of Engineering.

Along with 73 other leading figures in the field of engineering and technology, Prof. Williams was inducted into the Academy in a special ceremony on 28th November, officiated by HRH Princess Anne. In joining the Fellowship, they will lend their unique capabilities to achieving the Academy’s overarching strategic goal to harness the power of engineering to create a sustainable society and an inclusive economy for all.

More about Prof. Daryl Williams

Professor Daryl Williams is an internationally recognised expert in particle engineering and inventor of novel powder surface characterisation instruments, globally commercialised by his Surface Measurement Systems. The Dynamic Vapour Sorption (DVS) technique allows rapid determination of moisture sensitivity of powders, particularly drug formulations. It is used by every major pharmaceutical company in the world and in more than 1,000 universities and research laboratories.

His research group at Imperial College has consistently produced solutions for international companies on materials manufacture, characterization, and performance. As academic lead for the Imperial College Carbon Capture Pilot Plant he has pioneered hands-on engineering teaching, outreach and research on climate change mitigation.

A Message from Daryl

| It’s been an important year for Surface Measurement Systems globally, full of bold new steps for the business. Among the many exciting developments was the launch of our new contract analysis business, Particle Characterization Laboratories, in Hyderabad, India back in February. From there we’ve continued to grow and expand our sales and service teams across the world, elevating our customer engagement even further. This is coupled with an expansion of our research and development as well as the Science teams, to support our plans for product development. A key feature of 2023 has been new faces! As we expand the global ambitions for the business, I have had the pleasure of welcoming many new staff to Surface Measurement Systems globally.

The last 12 months saw the release not only of a brand-new website and online customer portal (www.sorptionhub.com), but Surface Measurement Systems also launched ground-breaking new instruments for developing new carbon capture materials; the DVS Carbon family. These products are being closely followed by two innovative Break Through Analysis (BTA) products; the BTA Horizon and BTA-Frontier. All of these products are receiving strong market interest. Of course, we continue to improve and develop our current products including a new family of improved microbalances and an updated IGC-SEA product including a high temperature capability. I would like to thank all of the Surface Measurement Systems staff for their dedication and hard work performed in 2023- we really do appreciate it. We look forward to continuing to serve the global sorption community with innovative solutions, unparalleled aftersales care, world-leading scientific support in an exciting 2024. Festive greetings from the Surface Measurement Systems team! |

SMS Employee Milestones

A few of our veteran employees have crossed some big milestones in the last year! We wanted to highlight the colleagues who have passed a significant market in the length of service they have dedicated to the company.

Thank you all for your invaluable contributions, we couldn’t have done it without you!